Spektral durchstimmbare DFB Laser für Anwendungen

in der Gasmessung

Tunable DFB lasers are a key feature in a wide variety of different

applications ranging from

process control to medical diagnostics |

Dr. Lars Hildebrandt, Vertrieb, nanoplus GmbH,

Gerbrunn

VDI-Fachkonferenz 16. - 17. Februar 2011 in Frankfurt am Main

|

|

|

DFB Laser versus FP Laserdiodes

DFB : Distributed Feedback Laser

FP LD : Fabry-Pérot

FP LD in an external cavity yield good tuning ranges as well as monomode spectra. Such

systems are available for high resolution spectroscopy at all wavelengths between 400 nm and

11 μm, however, they incorporate mechanical parts which make them hardly usable for industrial

environments, for field measurements or in production sites.

|

|

| |

|

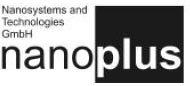

DFB Laser

This problem is overcome by

distributed feedback (DFB) lasers.

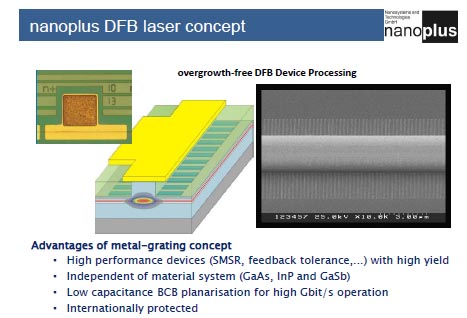

The key element for monomode emission and the tuning characteristics is the DFB-grating.

Through a special technology, based on lateral metal Bragg gratings incorporated in the laser

structure, it is nowadays possible to fabricate monomode emitting semiconductor lasers on any

III/V-based material, leading to a broad accessible wavelength range from 760 nm up to 3 μm.

In

this part of the spectrum many industrial and environmental gas species exhibit strong absorption

features. |

|

| |

|

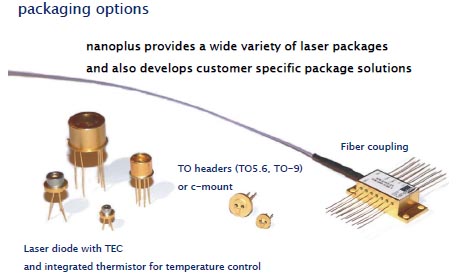

NIR DFB laser diodes and MIR lasers in various packing options

|

|

| |

|

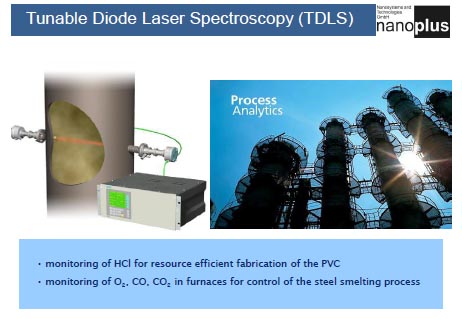

Process control

Process control has evolved as one of the most important fields of application for LD based gas

sensing.

One interesting sub-category thereof is combustion control.

By monitoring the

concentrations of gases generated during combustion processes, such as CO, CO2, O2, NH3, NOx and SO4, precise information about the conditions inside the combustion chamber can be obtained.

This information allows for a very efficient adjustment of the process conditions resulting in less

pollutant emission and higher process efficiency.

|

|

| Other application areas |

|

|

| |