August 2018

Industrial-scale demonstration plant for

climate-friendly chlorine production in

KrefeldUerdingen (Germany

Important advantages for energy-saving environmental-friendly chlorine production

- Decisive contribution to more environmentally-friendly and cost-effective chlorine production

- Advanced oxygen depolarized cathode (ODC) technology enables 50 percent more output and significantly lower investment costs

- Energy-saving process to be utilized for new chlorine production plant in Spain

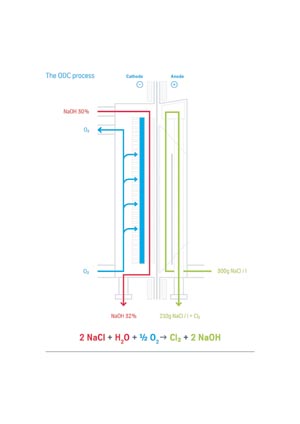

Oxygen depolarized cathode (ODC) technology

Around 70 percent of all chemical products use chlorine in their manufacturing process. At the same time, the production of this important base chemical is one of the most energyintensive processes in the chemical industry.

In order to change that, thyssenkrupp is offering the NaCl-ODC electrolysis technology (ODC = oxygen depolarized cathode) which

lowers power consumption and indirect CO2 emissions by up to 25 percent compared to standard production processes.

Advanced ODC technology reduces carbon footprint of chlorine production plants

thyssenkrupp’s cooperation partner Covestro will be the first to utilize the advanced ODC electrolysis for a new chlor-alkali plant in Tarragona, Spain. “Three factors played a vital role in choosing the technology for our process: sustainability, energy efficiency, and increasing our site’s competitiveness”, states Dr. Klaus Schäfer, Chief Technology Officer at Covestro.

Costefficient solution for the chlor-alkali industry

The original NaCl-ODC electrolysis was developed by combining two key technologies: The oxygen-depolarized cathodes developed by Covestro were integrated into the electrolysis cells (single element technology) from thyssenkrupp Uhde Chlorine Engineers.

By introducing oxygen into the cathode, the often unwanted formation of hydrogen is suppressed. The reaction is comparable to fuel cells, but here it lowers the electrical energy consumption instead of producing energy. This enables huge energy savings, which are highest when oxygen is available on site.

As energy prices are on the rise

and sustainability targets become more and more important, NaCl-ODC is an increasingly attractive option for future competitiveness in the chlor-alkali market.

As it is based on the general design of the single element technology, integration of this technology into existing plants can be done easily. Cell size and brine circulation are 100 percent compatible.

Plant owners can easily upgrade existing infrastructures either to lower electricity consumption, or to increase their production capacity without needing additional space or a new build. |