February 2019

Camera for Non-Destructive

Testing (NDT)

Non-Destructive Testing (NDT)

FLIR Systems reports how its FLIR A6700 series thermal cameras with Lock-In, Transient, and Pulse capabilities can perform advanced inspections such as Non-Destructive Testing (NDT) or stress mapping, resolving temperature

differences as low as 1 mK.

Properties of a material

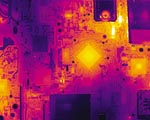

Non-Destructive Testing (NDT) is widely used to evaluate the properties of a material, component, or system without causing damage. FLIR A6700sc series cameras can detect internal defects through target excitation and the observation of thermal differences on a target's surface. Thermal imaging is a valuable tool for detecting defects and points of failure in composites, solar cells, bridges, and electronics. It is also a great tool for thermal mapping of stress when performing materials testing.

Thermal non-destructive testing using a FLIR A6750 SLS longwave infrared thermal camera can detect internal defects through target excitation andthe observation of thermal differences on a target surface. This camera is also proven to be a valuable tool for detecting voids, delamination, and water inclusion in composites.

For further information please visit https://www.flir.co.uk/instruments/science/ndt-materials-testing/ or contact FLIR Systems on +32-3665-5100 / research@flir.com.

|